Made in Germany

PAGEL Spezial-Beton in Essen

For five decades PAGEL® Spezial-Beton GmbH & Co. KG, Essen (Germany), has defined the development of grouts and mortars for special uses.

PAGEL® Grouts, including the well-known V1® brand, and PAGEL® Concrete Repair Mortars have become an internationally recognized quality standard.

Our company develops, produces and markets grout and mortar for special purposes for precision machinery, wind turbines and anchoring and injection works, as well as repair mortars for concrete, for potable water tanks and wastewater structures as well as for industrial floors and traffic areas.

Our comprehensive product range, the consistently high quality and high reliability of our products as well as good solution-oriented advice for our customers have given us the solid reputation that we enjoy worldwide.

The satisfaction of our customers will continue to be the central goal of our activities in the future.

Our materials laboratory

Product Development and Research

The PAGEL building materials laboratory

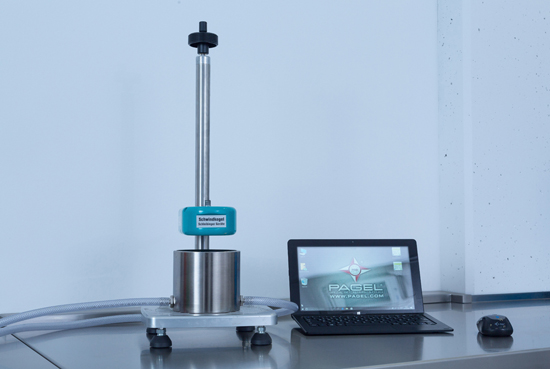

PAGEL has a modern, state-of-the-art building materials laboratory. In addition to mechanical test processes we can also measure the swelling and shrinkage deformation of materials, and much more besides. This considerably aids us in our product development.

Our products are tested for their practical suitability in a climate chamber and in climate cabinets in temperature ranges between -20 °C and +60 °C (-4°F and 140°F resp.).

Temperature tests

- Climate chamber for sample preparation and fresh concrete testing between -10 °C and +50 °C (14°F and 122°F)

- Climate cabinets for sample storage at temperatures between -20°C and +60°C (-4°F and 140°F) and air humidity between 0% and 100%

- Storage of test specimens in water between 5°C and 35°C (41°F and 95°F)

Measurement of deformations

Schleibinger shrinkage-cone at temperatures between +5°C and +35°C (41°F and 95°F) for testing the contraction and expansion behaviour.

Complementary tests

- Automatic Blaine value Determination

- Sieve analysis

- Vicat test: initial and final setting time

- Pull-off strength test

- Böhme's abrasion resistance test

- Acoustic analysis of the resonance frequency for non-aggressive testing of the dynamic and static Young's modulus

- Characteristics of newly poured mortar in accordance to DIN EN 12350, directive VeBMR and ASTM